Examination Weightings

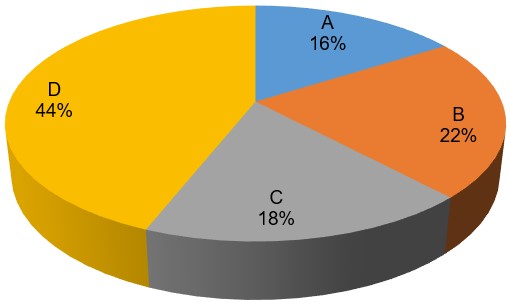

Pie Chart of Red Seal Examination Weightings

Text version

- Major Work Activity A - Performs common occupational skills 16%

- Major Work Activity B - Performs layout and fabrication of components for welding 22%

- Major Work Activity C - Performs cutting and gouging 18%

- Major Work Activity D - Performs welding processes 44%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. The Interprovincial examination for this trade has 125 questions.

Welder - Task Matrix and Weightings

Major Work Activity A – Performs common occupational skills 16%

- Task A-1 Maintains tools and equipment 25%

- A-1.01 Maintains hand, power, layout and measuring tools

- A-1.02 Maintains stationary machinery

- A-1.03 Maintains thermal cutting equipment

- A-1.04 Maintains welding equipment

- Task A-2 Uses access and material handling equipment 15%

- A-2.01 Uses access equipment

- A-2.02 Uses material handling equipment

- Task A-3 Performs safety-related activities 25%

- A-3.01 Performs hazard assessments

- A-3.02 Maintains safe work environment

- A-3.03 Uses personal protective equipment (PPE) and safety equipment

- Task A-4 Organizes work 15%

- A-4.01 Uses documentation and reference material

- A-4.02 Interprets drawings and welding symbols

- A-4.03 Plans job tasks

- A-4.04 Organizes materials

- Task A-5 Performs routine trade activities 28%

- A-5.01 Performs quality inspection

- A-5.02 Marks welds, materials and parts

- A-5.03 Controls temperature of weldments

- A-5.04 Stores welding consumables and gas cylinders

- A-5.05 Selects welding processes and power source

- A-5.06 Performs equipment start-up and shut-down

- A-5.07 Finishes final product

- Task A-6 Uses communication and mentoring techniques 2%

- A-6.01 Uses communication techniques

- A-6.02 Uses mentoring techniques

Major Work Activity B – Performs layout and fabrication of components for welding 22%

- Task B-7 Performs layout 44%

- B-7.01 Develops templates

- B-7.02 Transfers dimensions from drawings to materials

- Task B-8 Fabricates components 56%

- B-8.01 Prepares materials

- B-8.02 Fits components for welding

- B-8.03 Assembles components

Major Work Activity C – Performs cutting and gouging 18%

- Task C-9 Uses tools and equipment for non- thermal cutting and grinding 25%

- C-9.01 Selects cutting and grinding tools

- C-9.02 Cuts using stationary power tools

- C-9.03 Cuts using shears and ironworkers

- C-9.04 Cuts using hand tools

- C-9.05 Cuts using portable power tools

- Task C-10 Uses oxy-fuel gas cutting (OFC) process for cutting and gouging 30%

- C-10.01 Selects OFC gas and equipment

- C-10.02 Sets up OFC equipment

- C-10.03 Sets operating parameters for OFC equipment

- C-10.04 Performs cut and gouge using OFC equipment

- Task C-11 Uses plasma arc cutting (PAC) process for cutting and gouging 26%

- C-11.01 Selects PAC equipment and consumables

- C-11.02 Sets up PAC equipment

- C-11.03 Sets operating parameters for PAC equipment

- C-11.04 Performs cut and gouge using PAC equipment

- Task C-12 Uses air carbon arc cutting (CAC-A) process for cutting and gouging 19%

- C-12.01 Selects CAC-A equipment and consumables

- C-12.02 Sets up CAC-A equipment

- C-12.03 Sets operating parameters for CAC-A equipment

- C-12.04 Performs cut and gouge using CAC-A equipment

Major Work Activity D – Performs welding processes 44%

- Task D-13 Welds using shielded metal arc welding (SMAW) process 33%

- D-13.01 Selects SMAW equipment and consumables

- D-13.02 Sets up SMAW equipment

- D-13.03 Sets operating parameters for SMAW

- D-13.04 Performs weld using SMAW equipment

- Task D-14 Welds using flux cored arc welding (FCAW), metal cored arc welding (MCAW) and gas metal arc welding (GMAW) processes 34%

- D-14.01 Selects FCAW, MCAW and GMAW gas, equipment and consumables

- D-14.02 Sets up FCAW, MCAW and GMAW equipment

- D-14.03 Sets operating parameters for FCAW, MCAW and GMAW

- D-14.04 Performs weld using FCAW, MCAW and GMAW equipment

- Task D-15 Welds using gas tungsten arc welding (GTAW) process 24%

- D-15.01 Selects GTAW gas, equipment and consumables

- D-15.02 Sets up GTAW equipment

- D-15.03 Sets operating parameters for GTAW

- D-15.04 Performs weld using GTAW equipment

- Task D-16 Welds using submerged arc welding (SAW) process 9%

- D-16.01 Selects SAW equipment and consumables

- D-16.02 Sets up SAW equipment

- D-16.03 Sets operating parameters for SAW

- D-16.04 Performs weld using SAW equipment