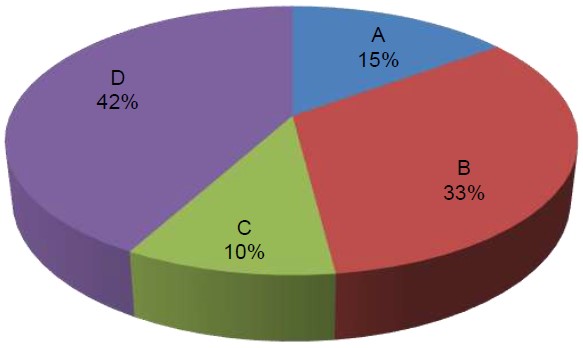

Examination Weightings

Pie Chart of Red Seal Examination Weightings

Text version

- MWA A - Performs common occupational skills 15%

- MWA B - Operates machine-tools 33%

- MWA C - Performs heat treatment 10%

- MWA D - Performs design and development of prototypes and production tools 42%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix on the next pages indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. The Interprovincial examination for this trade has 135 questions.

Tool and Die Maker - Task Matrix and Weightings

Major Work Activity A - Performs common occupational skills 15 %

- Task A-1 Performs safety-related functions 22 %

- A-1.01 Maintains safe work environment

- A-1.02 Uses personal protective equipment (PPE) and safety equipment

- A-1.03 Uses hoisting, lifting, rigging and supporting equipment

- Task A-2 Maintains machine-tools, accessories and cutting tools 17 %

- A-2.01 Maintains machine-tools and accessories

- A-2.02 Maintains cutting tools

- Task A-3 Organizes work 27 %

- A-3.01 Interprets drawings, specifications and applications

- A-3.02 Plans project activities

- Task A-4 Performs benchwork 24 %

- A-4.01 Performs layout

- A-4.02 Finishes workpiece

- A-4.03 Inspects workpiece

- Task A-5 Uses communication and mentoring techniques 10 %

- A-5.01 Uses communication techniques

- A-5.02 Uses mentoring techniques

Major Work Activity B - Operates machine-tools 33 %

- Task B-6 Operates power saws 9 %

- B-6.01 Sets up power saws

- B-6.02 Saws straight and angle cuts

- B-6.03 Cuts irregular shapes

- Task B-7 Operates drill presses 9 %

- B-7.01 Sets up drill presses

- B-7.02 Drills holes using drill presses

- B-7.03 Cuts countersinks, counterbores, chamfers and spot faces using drill presses

- B-7.04 Performs tapping using drill presses

- B-7.05 Finishes holes using drill presses

- Task B-8 Operates conventional lathes 19 %

- B-8.01 Sets up conventional lathes

- B-8.02 Faces surface using conventional lathes

- B-8.03 Turns internal and external surfaces using conventional lathes

- B-8.04 Creates holes using conventional lathes

- Task B-9 Operates conventional milling machines 20 %

- B-9.01 Sets up conventional milling machines

- B-9.02 Mills surfaces using conventional milling machines

- B-9.03 Creates holes and hole features using conventional milling machines

- Task B-10 Operates grinding machines 21 %

- B-10.01 Sets up grinding machines

- B-10.02 Grinds flat surfaces using a surface grinder

- B-10.03 Grinds profiles

- B-10.04 Grinds internal and external cylindrical and tapered surfaces

- B-10.05 Grinds tools and cutters

- B-10.06 Finishes holes using a honing machine

- Task B-11 Operates computer numerical control (CNC) machines 14 %

- B-11.01 Performs CNC programming

- B-11.02 Inputs program data into control memory

- B-11.03 Establishes workpiece datum

- B-11.04 Verifies programs

- B-11.05 Monitors machining processes

- Task B-12 Operates electrical discharge machines (EDM) 8 %

- B-12.01 Determines flushing methods

- B-12.02 Sets cutting conditions

Major Work Activity C - Performs heat treatment 10 %

- Task C-13 Heat treats materials 73 %

- C-13.01 Selects heat treatment process

- C-13.02 Hardens materials

- C-13.03 Tempers materials

- C-13.04 Anneals materials

- C-13.05 Normalizes materials

- C-13.06 Case hardens materials

- Task C-14 Tests heat treated materials 27 %

- C-14.01 Performs visual inspection

- C-14.02 Performs hardness test

Major Work Activity D - Performs design and development of prototypes and production tools 42 %

- Task D-15 Performs production tool design 15 %

- D-15.01 Identifies production tool requirements

- D-15.02 Prepares shop sketches

- D-15.03 Determines production tool material specifications and engineered components

- D-15.04 Prepares information for designing and drafting

- Task D-16 Develops prototype 11 %

- D-16.01 Selects prototyping technique and materials

- D-16.02 Fabricates prototype components

- D-16.03 Assembles prototype components

- D-16.04 Inspects prototype

- D-16.05 Proves out prototype

- Task D-17 Fits and assembles production tools 27 %

- D-17.01 Verifies dimensions of production tool components

- D-17.02 Performs production tool assembly

- D-17.03 Sets production tool timin

- Task D-18 Proves out production tools 24 %

- D-18.01 Sets up production tools

- D-18.02 Verifies production part materia

- D-18.03 Develops blank/strip

- D-18.04 Cycles equipment with production tools

- D-18.05 Evaluates production part

- D-18.06 Checks production tool for damage

- D-18.07 Modifies production tools to enhance productivity

- Task D-19 Repairs and maintains production tools 23 %

- D-19.01 Identifies condition of production tools

- D-19.02 Identifies repair procedures

- D-19.03 Adjusts production tool components

- D-19.04 Reconditions production tool components