Steamfitter/Pipefitter - Red Seal Examination Weightings

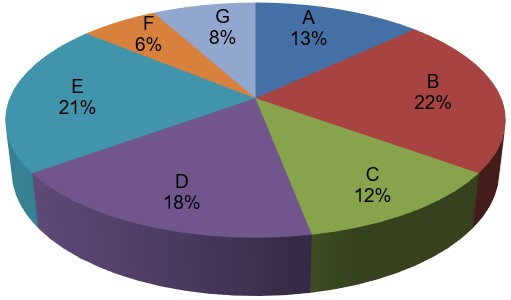

Pie Chart of Red Seal Examination Weightings

Text version

- MWA A - Performs common occupational skills 13%

- MWA B - Performs layout, fabrication and piping installation 22%

- MWA C - Performs rigging, hoisting, lifting and positioning 12%

- MWA D - Installs, tests, maintains, troubleshoots and repairs low and high pressure steam and condensate systems 18%

- MWA E - Installs, tests, maintains, troubleshoots and repairs heating, cooling and process piping systems 21%

- MWA F - Installs, tests, maintains, troubleshoots and repairs renewable energy systems 6%

- MWA G - Performs commissioning, start-up and turnover 8%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix on the next pages indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. The Interprovincial examination for this trade has 130 questions.

Steamfitter/Pipefitter Task Matrix and Weightings

MWA A - Performs common occupational skills 13%

- Task A-1 Performs safety-related functions 27%

- A-1.01 Maintains safe work environment

- A-1.02 Uses personal protective equipment (PPE) and safety equipment

- A-1.03 Follows lock-out and tag-out (LOTO) procedures

- Task A-2 Uses and maintains tools and equipment 37%

- A-2.01 Uses common tools and equipment

- A-2.02 Uses access equipment

- A-2.03 Uses welding equipment

- A-2.04 Uses soldering and brazing equipment

- A-2.05 Uses oxy-fuel and plasma cutting equipment

- Task A-3 Organizes job 23%

- A-3.01 Plans work

- A-3.02 Generates drawings

- A-3.03 Interprets drawings and specifications

- A-3.04 Develops piping templates

- A-3.05 Performs quality control functions

- A-3.06 Handles materials and components

- Task A-4 Uses communication and mentoring techniques 13%

- A-4.01 Uses communication techniques

- A-4.02 Uses mentoring techniques

MWA B – Performs layout, fabrication and piping installation 22%

- Task B-5 Performs fabrication 33%

- B-5.01 Fabricates piping system components

- B-5.02 Fabricates brackets, supports, hangers, guides and anchors

- Task B-6 Lays out and installs piping, tubing, fittings and related components 43%

- B-6.01 Lays out and installs copper tube, tubing, fittings and related components

- B-6.02 Lays out and installs plastic piping, fittings and related components

- B-6.03 Lays out and installs carbon steel piping, fittings and related components

- B-6.04 Lays out and installs stainless steel piping, tubing, fittings and related components

- B-6.05 Lays out and installs fibreglass piping, fittings and related components

- B-6.06 Lays out and installs specialty piping, fittings and related components

- Task B-7 Installs, maintains, troubleshoots, repairs and tests valves 14%

- B-7.01 Installs valves

- B-7.02 Maintains, troubleshoots, repairs and tests valves

- Task B-8 Installs, tests, maintains, troubleshoots and repairs heat tracing systems 10%

- B-8.01 Installs steam tracing systems

- B-8.02 Maintains, troubleshoots, repairs and tests steam tracing systems

- B-8.03 Installs liquid-filled tracing systems

- B-8.04 Maintains, troubleshoots, repairs and tests liquid-filled tracing systems

MWA C – Performs rigging, hoisting, lifting and positioning 12%

- Task C-9 Performs common rigging, hoisting, lifting and positioning 66%

- C-9.01 Determines load

- C-9.02 Prepares lift plan(s) for common rigging, hoisting, lifting and positioning

- C-9.03 Selects rigging, hoisting, lifting and positioning equipment for common lifts

- C-9.04 Inspects rigging, hoisting, lifting and positioning equipment

- C-9.05 Secures lift area

- C-9.06 Sets up rigging, hoisting, lifting and positioning equipment for common lifts

- C-9.07 Performs common lift and positioning

- C-9.08 Maintains and stores rigging, hoisting, lifting and positioning equipment

- Task C-10 Performs complex and critical rigging, hoisting, lifting and positioning 34%

- C-10.01 Prepares lift plan for complex and critical rigging, hoisting, lifting and positioning

- C-10.02 Performs calculations for complex and critical rigging, hoisting, lifting and positioning

- C-10.03 Selects rigging, hoisting, lifting and positioning equipment for complex and critical lifts

- C-10.04 Sets up rigging, hoisting, lifting and positioning equipment for complex and critical lifts

- C-10.05 Performs complex and critical lifts and positioning

MWA D – Installs, tests, maintains, troubleshoots and repairs low and high pressure steam and condensate systems 18%

- Task D-11 Installs, tests, maintains, troubleshoots and repairs low pressure steam and condensate systems 43%

- D-11.01 Installs equipment for low pressure steam and condensate systems

- D-11.02 Installs piping for low pressure steam and condensate systems

- D-11.03 Tests low pressure steam and condensate systems

- D-11.04 Maintains, troubleshoots and repairs low pressure steam and condensate systems

- Task D-12 Installs, tests, maintains, troubleshoots and repairs high pressure steam and condensate systems 57%

- D-12.01 Installs equipment for high pressure steam and condensate systems

- D-12.02 Installs piping for high pressure steam and condensate systems

- D-12.03 Tests high pressure steam and condensate systems

- D-12.04 Maintains, troubleshoots and repairs high pressure steam and condensate systems

MWA E – Installs, tests, maintains, troubleshoots and repairs heating, cooling and process piping systems 21%

- Task E-13 Installs, tests, maintains, troubleshoots and repairs hydronic systems 21%

- E-13.01 Installs equipment for hydronic systems

- E-13.02 Installs piping for hydronic systems

- E-13.03 Tests hydronic systems

- E-13.04 Maintains, troubleshoots and repairs hydronic systems

- Task E-14 Installs, tests, maintains, troubleshoots and repairs process piping systems 18%

- E-14.01 Installs equipment for process piping systems

- E-14.02 Installs piping for process piping systems

- E-14.03 Tests process piping systems

- E-14.04 Maintains, troubleshoots and repairs process piping systems

- Task E-15 Installs, tests, maintains, troubleshoots and repairs industrial water and waste treatment systems 12%

- E-15.01 Installs equipment for industrial water and waste treatment systems

- E-15.02 Installs piping for industrial water and waste treatment systems

- E-15.03 Tests industrial water and waste treatment systems

- E-15.04 Maintains, troubleshoots and repairs industrial water and waste treatment systems

- Task E-16 Installs, tests, maintains, troubleshoots and repairs hydraulic systems 10%

- E-16.01 Installs equipment for hydraulic systems

- E-16.02 Installs piping and hoses for hydraulic systems

- E-16.03 Tests hydraulic systems

- E-16.04 Maintains, troubleshoots and repairs hydraulic systems

- Task E-17 Installs, tests, maintains, troubleshoots and repairs heating, ventilation, air conditioning and refrigeration (HVACR) systems 9%

- E-17.01 Installs equipment for HVACR systems

- E-17.02 Installs piping for HVACR systems

- E-17.03 Tests HVACR systems

- E-17.04 Maintains, troubleshoots and repairs HVACR systems

- Task E-18 Installs, tests, maintains, troubleshoots and repairs fuel systems 10%

- E-18.01 Installs equipment for fuel systems

- E-18.02 Installs piping for fuel systems

- E-18.03 Tests fuel systems

- E-18.04 Maintains, troubleshoots and repairs fuel systems

- Task E-19 Installs, tests, maintains, troubleshoots and repairs medical gas systems 9%

- E-19.01 Installs equipment for medical gas systems

- E-19.02 Installs piping for medical gas systems

- E-19.03 Tests medical gas systems

- E-19.04 Maintains, troubleshoots and repairs medical gas systems

- Task E-20 Installs, tests, maintains, troubleshoots and repairs compressed air and pneumatic systems 11%

- E-20.01 Installs equipment for compressed air and pneumatic systems

- E-20.02 Installs piping for compressed air and pneumatic systems

- E-20.03 Tests compressed air and pneumatic systems

- E-20.04 Maintains, troubleshoots and repairs compressed air and pneumatic systems

- Task E-21 Installs and tests fire protection systems 0% - Not Common Core

- E-21.01 Installs equipment for fire protection systems- Not Common Core

- E-21.02 Installs piping for fire protection systems- Not Common Core

- E-21.03 Tests fire protection systems- Not Common Core

MWA F – Installs, tests, maintains, troubleshoots and repairs renewable energy systems 6%

- Task F-22 Installs, tests, maintains, troubleshoots and repairs geo-exchange and geothermal systems 27%

- F-22.01 Installs equipment for geo-exchange and geothermal systems

- F-22.02 Installs piping for geo-exchange and geo-thermal systems

- F-22.03 Tests geo-exchange and geothermal systems

- F-22.04 Maintains, troubleshoots and repairs geo-exchange and geothermal systems

- Task F-23 Installs, tests, maintains, troubleshoots and repairs solar heating systems 23%

- F-23.01 Installs equipment for solar heating systems

- F-23.02 Installs piping for solar heating systems

- F-23.03 Tests solar heating systems

- F-23.04 Maintains, troubleshoots and repairs solar heating systems

- Task F-24 Installs, tests, maintains, troubleshoots and repairs heat recovery systems 50%

- F-24.01 Installs equipment for heat recovery systems

- F-24.02 Installs piping for heat recovery systems

- F-24.03 Tests heat recovery systems

- F-24.04 Maintains, troubleshoots and repairs heat recovery systems

MWA G – Performs commissioning, start-up and turnover 8%

- Task G-25 Prepares system for commissioning, start-up and turnover 55%

- G-25.01 Flushes system

- G-25.02 Chemically treats system

- G-25.03 Pre-checks system for commissioning

- G-25.04 Selects and connects commissioning equipment

- Task G-26 Commissions systems 45%

- G-26.01 Secures commissioning area

- G-26.02 Pressurizes system

- G-26.03 Inspects system

- G-26.04 Corrects faulty conditions

- G-26.05 Participates in start-up and turnover procedures