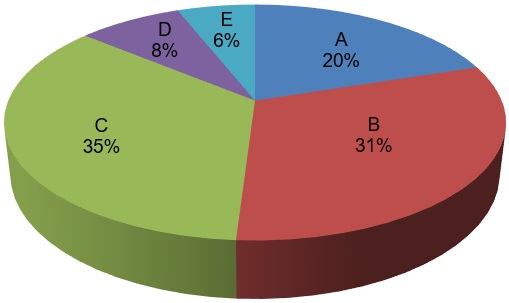

Sheet Metal Worker Red Seal examination Weightings

MWA A - Performs common occupational skills 20%

MWA B - Performs fabrication 31%

MWA C - Installs air and material handling systems 35%

MWA D - Installs roofing and specialty products 8%

MWA E - Performs maintenance and repair 6%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix on the next pages indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. Interprovincial examinations for this trade have 120 questions.

MWA A - Performs common occupational skills 20%

1. Task A-1 Performs safety-related functions 22%

- A-1.01 Uses personal protective equipment (PPE) and safety equipment

- A-1.02 Maintains safe work environment

- A-1.03 Performs lock-out and tag-out procedures

2. Task A-2 Uses and maintains tools and equipment 39%

- A-2.01 Uses hand and portable power tools

- A-2.02 Uses shop tools and equipment

- A-2.03 Uses gas metal arc welding (GMAW) equipment

- A-2.04 Uses resistance spot welding equipment

- A-2.05 Uses gas tungsten arc welding (GTAW) equipment

- A-2.06 Uses shielded metal arc welding (SMAW) equipment

- A-2.07 Uses oxy-fuel and plasma arc cutting equipment

- A-2.08 Uses soldering and brazing equipment

- A-2.09 Uses measuring and layout equipment

- A-2.10 Uses testing and inspection devices

- A-2.11 Uses stationary and mobile work platforms

- A-2.12 Uses hoisting, rigging and positioning equipment

3. Task A-3 Organizes work 26%

- A-3.01 Uses trade-related documentation

- A-3.02 Interprets drawings

- A-3.03 Organizes materials and equipment for project

- A-3.04 Performs basic design and field modifications

4. Task A-4 Uses communication and mentoring techniques 13%

- A-4.01 Uses communication techniques

- A-4.02 Uses mentoring techniques

MWA B - Performs fabrication 31%

5. Task B-5 Performs pattern development 33%

- B-5.01 Develops patterns using simple and straight line layout

- B-5.02 Develops patterns using parallel line method

- B-5.03 Develops patterns using radial line method

- B-5.04 Develops patterns using triangulation method

- B-5.05 Uses computer technology for pattern development

6. Task B-6 Fabricates sheet metal components for air and material handling systems 42%

- B-6.01 Cuts ductwork, fittings and components

- B-6.02 Forms ductwork, fittings and components

- B-6.03 Insulates ductwork, fittings and components

- B-6.04 Assembles ductwork, fittings and components

- B-6.05 Fabricates dampers

- B-6.06 Fabricates hanger systems, supports and bases

7. Task B-7 Fabricates flashing, roofing, sheeting and cladding 9%

- B-7.01 Cuts metal for flashing, roofing, sheeting and cladding

- B-7.02 Forms flashing, roofing, sheeting and cladding

8. Task B-8 Fabricates specialty products 16%

- B-8.01 Cuts material for specialty products

- B-8.02 Forms specialty products

- B-8.03 Assembles specialty products

- B-8.04 Finishes specialty products

MWA C - Installs air and material handling systems 35%

9. Task C-9 Prepares installation site 17%

- C-9.01 Performs on-site measurements

- C-9.02 Performs demolitions for renovations

- C-9.03 Installs penetrations and sleeves

- C-9.04 Installs supports and bases

- C-9.05 Installs hangers, cables, braces and brackets

10. Task C-10 Installs and connects chimneys, breeching and venting to exhaust appliances and mechanical equipment 15%

- C-10.01 Installs chimney

- C-10.02 Connects appliances or mechanical equipment to chimney and breeching

- C-10.03 Installs high efficiency appliances and mechanical equipment

11. Task C-11 Installs air handling system components 39%

- C-11.01 Installs air handling equipment

- C-11.02 Installs sheet metal ducts and fittings

- C-11.03 Installs dampers

- C-11.04 Installs fire and fire/smoke dampers

- C-11.05 Installs registers, grilles, diffusers and louvers

- C-11.06 Installs terminal boxes

- C-11.07 Installs coils

- C-11.08 Installs system component accessories

- C-11.09 Installs plenums

12. Task C-12 Installs material handling system components 12%

- C-12.01 Installs pneumatic and gravity material handling system components

- C-12.02 Installs mechanized material handling system components

13. Task C-13 Applies thermal insulation, lagging, cladding and flashing 8%

- C-13.01 Applies thermal insulation to components

- C-13.02 Applies lagging and cladding to components

- C-13.03 Applies flashing to components

14. Task C-14 Performs leak testing, air balancing and commissioning 9%

- C-14.01 Performs leak tests

- C-14.02 Performs testing, adjusting and balancing (TAB)

- C-14.03 Participates in the commissioning of air and material handling systems

MWA D - Installs roofing and specialty products 8%

15. Task D-15 Installs metal roofing and cladding/siding systems 27%

- D-15.01 Lays out roof and walls

- D-15.02 Installs insulation, isolation material and building envelope components

- D-15.03 Installs roofing and cladding/siding system components

- D-15.04 Seals exposed joints

- D-15.05 Installs decking

16. Task D-16 Installs exterior components 21%

- D-16.01 Prepares surface

- D-16.02 Fastens exterior components

17. Task D-17 Installs specialty products 52%

- D-17.01 Installs stainless steel specialty products

- D-17.02 Installs non-stainless steel specialty products

- D-17.03 Installs marine products (Not Common Core)

MWA E - Performs maintenance and repair 6%

18. Task E-18 Performs scheduled maintenance 38%

- E-18.01 Performs maintenance inspections

- E-18.02 Services components

19. Task E-19 Repairs faulty systems and components 62%

- E-19.01 Diagnoses system faults

- E-19.02 Repairs worn or faulty components