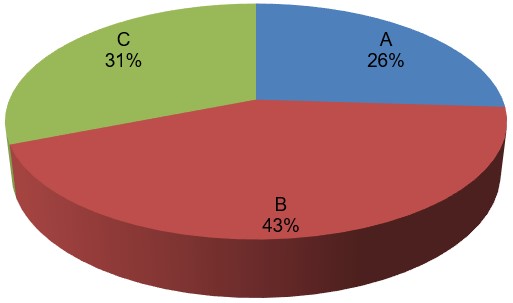

Red Seal Examination Weightings - Metal Fabricator (Fitter)

Pie Chart of Red Seal Examination Weightings

Text version

- MWA A - Performs common occupational skills 26%

- MWA B - Fabricates components 43%

- MWA C - Assembles components 31%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix on the next pages indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. The Interprovincial examination for this trade has 130 questions.

Metal Fabricator (Fitter) Task Matrix

MWA A – Performs common occupational skills 26%

- Task A-1 Performs safety-related functions 17%

- A-1.01 Maintains safe work environment

- A-1.02 Uses personal protective equipment (PPE) and safety equipment

- Task A-2 Uses and maintains tools and equipment 19%

- A-2.01 Uses hand, power, layout and measuring tools and equipment

- A-2.02 Uses stationary machinery

- A-2.03 Maintains cutting and welding equipment

- A-2.04 Uses access equipment

- Task A-3 Organizes work 17%

- A-3.01 Interprets plans, drawings and specifications

- A-3.02 Organizes project tasks

- Task A-4 Performs quality assurance throughout fabrication and assembly process 20%

- A-4.01 Performs visual inspections

- A-4.02 Verifies measurements, welds and layout

- A-4.03 Tracks materials and parts for traceability

- Task A-5 Handles materials 18%

- A-5.01 Organizes material

- A-5.02 Determines weights

- A-5.03 Applies rigging practices

- A-5.04 Operates material handling equipment

- Task A-6 Uses communication and mentoring techniques 9%

- A-6.01 Uses communication techniques

- A-6.02 Uses mentoring techniques

MWA B – Fabricates components 43%

- Task B-7 Performs layout 41%

- B-7.01 Performs pattern development

- B-7.02 Calculates material allowances for various processes

- B-7.03 Determines dimensions

- B-7.04 Transfers dimensions

- B-7.05 Makes templates

- Task B-8 Cuts materials 31%

- B-8.01 Cuts material using plasma cutting equipment

- B-8.02 Cuts material using oxy-fuel cutting equipment

- B-8.03 Cuts material using shears

- B-8.04 Cuts material using saws

- B-8.05 Cuts material using ironworkers

- B-8.06 Cuts material using computer numerically controlled (CNC) equipment

- B-8.07 Drills holes

- B-8.08 Cuts threads

- B-8.09 Prepares joints

- Task B-9 Forms materials 28%

- B-9.01 Forms materials using plate rollers

- B-9.02 Forms material using shape rollers

- B-9.03 Forms material using conventional and computer numerically controlled (CNC) press brakes

- B-9.04 Forms materials using benders

- B-9.05 Applies heat for forming

MWA C – Assembles components 31%

- Task C-10 Fits and fastens sub-components and components 48%

- C-10.01 Assembles jigs

- C-10.02 Determines sequence for assembly

- C-10.03 Assembles sub-components and components

- C-10.04 Sets fabricated components in place

- C-10.05 Joins components on-site

- Task C-11 Performs welding activities 31%

- C-11.01 Applies heat prior to tack welding

- C-11.02 Performs tack welding

- C-11.03 Minimizes welding distortions

- C-11.04 Applies welding processes

- C-11.05 Corrects welding distortions

- Task C-12 Completes project 21%

- C-12.01 Identifies type of finish

- C-12.02 Prepares material for finishing