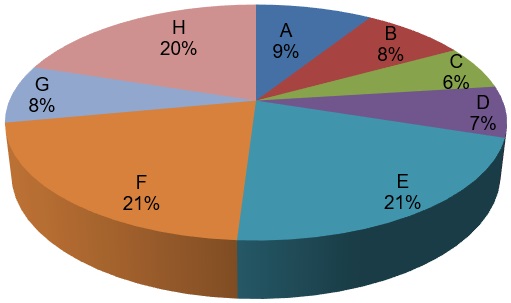

Machinist: Red Seal Examination Weightings

MWA A - Performs common occupational skills

MWA B - Performs benchwork

MWA C - Machines using power saws

MWA D - Machines using drill presses

MWA E - Machines using conventional lathes 21%

MWA F - Machines using conventional milling machines 21%

MWA G - Machines using precision grinding machines 8%

MWA H - Machines using computer numerical control (CNC) machines 20%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada.

The following is the list of all of the Major Work Activities, Tasks and Sub-tasks. The percentages represent how the questions are assigned to each Major Work Activity and Task. Interprovincial examinations for this trade have 100 questions.

MWA A - Performs common occupational skills 9%

1. Task A-1 Performs safety-related tasks 16%

- 1.01 Maintains safe work environment

- 1.02 Uses personal protective equipment (PPE) and safety equipment

2. Task A-2 Organizes work 25%

- 2.01 Interprets documentation

- 2.02 Plans sequence of operations

3. Task A-3 Uses communication and mentoring techniques 14%

- 3.01 Uses communication techniques

- 3.02 Uses mentoring techniques

4. Task A-4 Processes workpiece material 27%

- 4.01 Selects workpiece material

- 4.02 Uses hoisting, lifting and rigging equipment

- 4.03 Marks workpiece for identification

- 4.04 Performs heat treatment

- 4.05 Performs quality control of workpiece

- 4.06 Deburrs workpiece

- 4.07 Sketches parts

5. Task A-5 Maintains machines, and inspection equipment tooling 18%

- 5.01 Cleans machines

- 5.02 Lubricates machines

- 5.03 Sharpens tooling

- 5.04 Applies cutting fluid and coolant

- 5.05 Troubleshoots equipment

- 5.06 Maintains machine alignment

- 5.07 Maintains inspection equipment

MWA B - Performs benchwork 8%

6. Task B-6 Performs hand processes 69%

- 6.01 Performs layout

- 6.02 Saws workpiece

- 6.03 Files workpiece

- 6.04 Performs hole making operations

- 6.05 Performs threading operations

- 6.06 Installs thread inserts

- 6.07 Broaches workpiece

- 6.08 Performs pressing operations

- 6.09 Forms workpiece

- 6.10 Finishes workpiece

7. Task B-7 Refurbishes components 31%

- 7.01 Disassembles components

- 7.02 Analyzes components

- 7.03 Assembles components

MWA C - Machines using power saws 6%

8. Task C-8 Sets up power saws 63%

- 8.01 Selects power saw types

- 8.02 Selects saw blades

- 8.03 Installs saw blades

- 8.04 Selects power saw speeds and feeds

- 8.05 Makes power saw adjustments

- 8.06 Sets up workpiece on power saw

9. Task C-9 Operates power saws 37%

- 9.01 Saws straight and angle cuts

- 9.02 Cuts irregular shapes

MWA D - Machines using drill presses 56%

10. Task D-10 Sets up drill presses 56%

- 10.01 Selects drill press types

- 10.02 Plans operation of drill presses

- 10.03 Selects drill press speeds and feeds

- 10.04 Sets up jigs, fixtures and work holding devices for drill presses

- 10.05 Sets up tooling for drill presses

11. Task D-11 Operates drill presses 44%

- 11.01 Drills holes using a drill press

- 11.02 Cuts countersinks, counterbores, chamfers and spot faces using a drill press

- 11.03 Performs tapping using a drill press

- 11.04 Finishes holes using a drill press

MWA E - Machines using conventional lathes 21%

12. Task E-12 Sets up conventional lathes 50%

- 12.01 Selects conventional lathe types

- 12.02 Plans operation of conventional lathes

- 12.03 Sets up work holding devices for conventional lathes

- 12.04 Sets up tooling for conventional lathes

- 12.05 Sets up conventional lathe accessories

- 12.06 Sets up workpiece on conventional lathe

- 12.07 Selects conventional lathe speeds and feeds

13. Task E-13 Operates conventional lathes 50%

- 13.01 Faces surfaces using a conventional lathe

- 13.02 Turns external surfaces using a conventional lathe

- 13.03 Drills using a conventional lathe

- 13.04 Bores holes using a conventional lathe

- 13.05 Reams holes using a conventional lathe

- 13.06 Turns tapers using a conventional lathe

- 13.07 Knurls using a conventional lathe

- 13.08 Cuts grooves using a conventional lathe

- 13.09 Cuts threads using a conventional lathe

- 13.10 Parts off workpiece using a conventional lathe

MWA F - Machines using conventional milling machines 21%

14. Task F-14 Sets up conventional milling machines 53%

- 14.01 Selects conventional milling machine types

- 14.02 Plans operation of milling machines

- 14.03 Sets up work holding devices for conventional milling machines

- 14.04 Sets up tooling for conventional milling machines

- 14.05 Sets up milling accessories

- 14.06 Sets up workpiece on a conventional milling machine

- 14.07 Selects conventional milling machine speeds and feeds

15. Task F-15 Operates conventional milling machines 47%

- 15.01 Mills surfaces using a conventional milling machine

- 15.02 Mills profiles and pockets using a conventional milling machine

- 15.03 Mills slots, grooves and keyways using a conventional milling machine

- 15.04 Cuts gears and splines using a conventional milling machine

- 15.05 Drills holes using a conventional milling machine

- 15.06 Reams holes using a conventional milling machine

- 15.07 Cuts countersinks, counterbores, chamfers and spot faces using a conventional milling machine

- 15.08 Performs tapping using a conventional milling machine

- 15.09 Bores holes using a conventional milling machine

MWA G - Machines using precision grinding machines 8%

16. Task G-16 Sets up precision grinding machines 59%

- 16.01 Selects precision grinding machine types

- 16.02 Plans operation of grinding machines

- 16.03 Sets up work holding devices for precision grinding machines

- 16.04 Mounts grinding wheel

- 16.05 Sets up grinding accessories

- 16.06 Sets up workpiece on precision grinding machines

- 16.07 Selects precision grinding machine speeds and feeds

17. Task G-17 Operates precision grinding machines 41%

- 17.01 Grinds flat surfaces using a surface grinder

- 17.02 Grinds profiles

- 17.03 Grinds internal and external cylindrical and tapered surfaces

- 17.04 Grinds tools and cutters

- 17.05 Finishes holes using a honing machine

MWA H - Machines using computer numerical control (CNC) machines 20%

18. Task H-18 Performs CNC programming 43%

- 18.01 Creates process documentation

- 18.02 Creates manual input program

- 18.03 Transfers program to and from control memory

- 18.04 Optimizes program

- 18.05 Creates 2D and 3D models

- 18.06 Programs using computer-aided manufacturing (CAM)

19. Task H-19 Sets up CNC machines 31%

- 19.01 Selects tooling and tool holders for CNC machines

- 19.02 Sets up tooling and tool holders on CNC machines

- 19.03 Sets up workpieces on CNC machines

- 19.04 Establishes work datum

- 19.05 Verifies program

20. Task H-20 Operates CNC machines 26%

- 20.01 Adjusts offsets

- 20.02 Monitors machining processes

- 20.03 Interrupts program cycle

- 20.04 Restarts program cycle