Lather (Interior Systems Mechanic) - Red Seal Examination Weightings

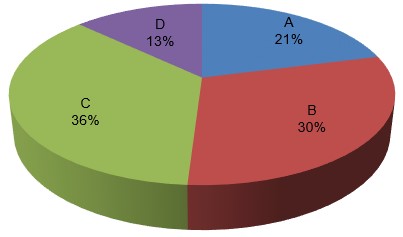

Pie chart of Red Seal examination weightings

Text version

- MWA A Performs common occupational skills 21%

- MWA B Performs framing activities 30%

- MWA C Installs interior systems 36%

- MWA D Installs exterior systems 13%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix on the next pages indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. The Interprovincial examination for this trade has 125 questions.

Lather (Interior Systems Mechanic) - Task matrix

MWA A – Performs common occupational skills 21%

- Task A-1 Performs safety-related functions 11%

- A-1.01 Maintains safe work environment

- A-1.02 Uses personal protective equipment (PPE) and safety equipment

- Task A-2 Uses tools and equipment 23%

- A-2.01 Uses hand tools

- A-2.02 Uses power tools and equipment

- A-2.03 Uses powder-actuated tools

- A-2.04 Uses gas-actuated tools

- A-2.05 Uses pneumatic tools (NOT COMMON CORE)

- A-2.06 Uses layout and measuring devices

- A-2.07 Uses scaffolding and access equipment

- Task A-3 Organizes work 26%

- A-3.01 Uses documentation and reference materials

- A-3.02 Uses blueprints and drawings

- A-3.03 Plans project tasks

- A-3.04 Estimates materials and supplies

- Task A-4 Performs routine trade activities 29%

- A-4.01 Performs measurements

- A-4.02 Uses jigs and templates

- A-4.03 Handles materials, supplies and products

- A-4.04 Lays out work

- A-4.05 Applies sealants and gaskets

- Task A-5 Uses communication and mentoring techniques 11%

- A-5.01 Uses communication techniques

- A-5.02 Uses mentoring techniques

MWA B – Performs framing activities 30%

- Task B-6 Erects non-loadbearing steel assemblies 60%

- B-6.01 Frames non-loadbearing walls

- B-6.02 Frames spanned ceilings

- B-6.03 Frames suspended drywall ceilings

- B-6.04 Frames non-loadbearing bulkheads

- B-6.05 Installs metal door and window frames

- B-6.06 Installs backing

- Task B-7 Erects loadbearing steel assemblies 40%

- B-7.01 Frames loadbearing walls

- B-7.02 Frames exterior ceilings and soffits

- B-7.03 Frames loadbearing bulkheads

- B-7.04 Frames loadbearing floors

- B-7.05 Frames loadbearing roofs

MWA C – Installs interior systems 36%

- Task C-8 Installs wall systems and components 32%

- C-8.01 Installs demountable walls

- C-8.02 Installs drywall

- C-8.03 Finishes drywall

- C-8.04 Installs drywall trims and mouldings

- C-8.05 Installs security mesh

- C-8.06 Installs access panels

- Task C-9 Installs ceiling systems 31%

- C-9.01 Installs suspended ceilings

- C-9.02 Installs non-suspended ceilings

- Task C-10 Installs access flooring systems 6%

- C-10.01 Installs pedestals and supporting hardware

- C-10.02 Installs flooring panels

- Task C-11 Installs sound barriers and lead radiation shielding 11%

- C-11.01 Installs sound barriers

- C-11.02 Installs lead radiation shielding

- Task C-12 Installs smoke and fire barriers 20%

- C-12.01 Installs shaft wall systems

- C-12.02 Seals penetrations

- C-12.03 Encloses beams, columns and staircases to achieve desired fire rating

MWA D – Installs exterior systems 13%

- Task D-13 Installs insulation and membranes 48%

- D-13.01 Installs thermal insulation

- D-13.02 Installs interior/exterior membranes

- Task D-14 Prepares surface for exterior finishes 36%

- D-14.01 Installs exterior sheathing

- D-14.02 Installs lath

- D-14.03 Installs Exterior Insulation Finish System (EIFS) (NOT COMMON CORE)

- Task D-15 Installs exterior finishes 16%

- D-15.01 Fabricates panels

- D-15.02 Installs pre-manufactured panels