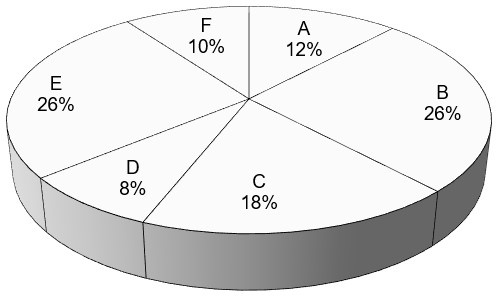

Examination Weightings

Pie Chart of Red Seal Examination Weightings

Text version

- Major Work Activity A - Performs common occupational skills 12%

- Major Work Activity B - Performs rigging, hoisting and positioning, and mobilization, erection, and demobilization of cranes 26%

- Major Work Activity C - Fabricates and installs reinforcing materials 18%

- Major Work Activity D - Performs pre-stressing/post-tensioning 08%

- Major Work Activity E - Performs erection, assembly and installation 26%

- Major Work Activity F - Performs maintenance and upgrading 10%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. The Interprovincial examination for this trade has 120 questions.

Ironworker (Generalist) - Task Matrix and Weightings

Major Work Activity A – Performs common occupational skills 12%

- Task A-1 Maintains safe and healthy workplace 28%

- A-1.01 Maintains safe work environment

- A-1.02 Uses personal protective equipment (PPE) and safety equipment

- A-1.03 Participates in healthy and respectful work environment

- Task A-2 Uses and maintains tools and equipment 38%

- A-2.01 Uses hand tools and measuring equipment

- A-2.02 Uses power tools

- A-2.03 Uses bending tools and equipment

- A-2.04 Uses powder-actuated tools

- A-2.05 Uses mobile elevating work platforms (MEWP)

- A-2.06 Uses material handling equipment

- A-2.07 Uses ladders

- A-2.08 Uses scaffolding

- A-2.09 Uses surveying equipment

- A-2.10 Uses welding equipment

- A-2.11 Uses mechanical cutting equipment

- A-2.12 Uses thermal cutting equipment

- Task A-3 Organizes work 24%

- A-3.01 Organizes materials and supplies

- A-3.02 Performs layout

- A-3.03 Uses drawings and documentation

- A-3.04 Plans tasks

- Task A-4 Maintains continuous learning 5%

- A-4.01 Upskills in new trade practices and procedures

- A-4.02 Upskills in emerging technologies

- Task A-5 Uses communication and mentoring techniques 5%

- A-5.01 Uses communication techniques

- A-5.02 Uses mentoring techniques

Major Work Activity B - Performs rigging, hoisting and positioning, and mobilization, erection, and demobilization of cranes 26%

- Task B-6 Plans lift 24%

- B-6.01 Assesses load

- B-6.02 Performs pre-lift analysis

- B-6.03 Selects rigging, hoisting and positioning equipment

- B-6.04 Secures lift area

- Task B-7 Rigs, hoists and positions load 35%

- B-7.01 Inspects rigging, hoisting and positioning equipment

- B-7.02 Assembles rigging, hoisting and positioning equipment

- B-7.03 Attaches rigging equipment to load

- B-7.04 Performs hoisting and positioning operations

- B-7.05 Secures load before rigging removal

- Task B-8 Performs post-lift activities 20%

- B-8.01 Conducts post-lift inspection

- B-8.02 Disassembles rigging, hoisting and positioning equipment

- B-8.03 Maintains rigging, hoisting and positioning equipment

- Task B-9 Performs mobilization, erection and demobilization of cranes 21%

- B-9.01 Mobilizes telescopic boom cranes

- B-9.02 Erects lattice boom cranes, tower cranes, derricks and components

- B-9.03 Performs demobilization and disassembly of cranes

Major Work Activity C - Fabricates and installs reinforcing material 18%

- Task C-10 Fabricates reinforcing materials on-site 34%

- C-10.01 Cuts reinforcing materials

- C-10.02 Bends reinforcing materials

- Task C-11 Installs reinforcing materials 66%

- C-11.01 Places reinforcing materials

- C-11.02 Ties reinforcing materials

- C-11.03 Splices reinforcing materials

Major Work Activity D - Performs pre-stressing/post-tensioning 8%

- Task D-12 Places pre-stressed/post-tensioning systems 57 %

- D-12.01 Lays out profile

- D-12.02 Places tendons and accessories

- D-12.03 Installs bursting steel and anchorages

- D-12.04 Connects tendons to anchorages

- D-12.05 Protects exposed tendons

- Task D-13 Stresses tendons 30%

- D-13.01 Sets up stressing equipment

- D-13.02 Tensions tendons

- D-13.03 Cuts and caps tendons

- D-13.04 Removes stressing equipment

- D-13.05 De-stresses tendons

- Task D-14 Grouts tendons 13%

- D-14.01 Sets up grouting equipment

- D-14.02 Installs grout

Major Work Activity E - Performs erection, assembly and installation 26%

- Task E-15 Installs primary and secondary structural members 51 %

- E-15.01 Uses falsework

- E-15.02 Attaches structural members

- E-15.03 Levels, plumbs and aligns structural members

- E-15.04 Completes installation of structural members

- Task E-16 Installs ornamental, miscellaneous, and steel cladding systems and components 26%

- E-16.01 Installs curtain walls and window walls

- E-16.02 Installs miscellaneous components

- E-16.03 Installs steel cladding, and building envelope systems and components

- Task E-17 Installs conveyors, machinery and equipment 23%

- E-17.01 Installs material handling systems

- E-17.02 Performs alignment and commissioning of material handling systems

Major Work Activity F - Performs maintenance and upgrading 10%

- Task F-18 Decommissions, disassembles and removes structural, ornamental, mechanical and miscellaneous components 60%

- F-18.01 Ensures decommissioning of structure and components

- F-18.02 Disassembles structural, ornamental, mechanical and miscellaneous components

- Task F-19 Maintains and repairs components 40%

- F-19.01 Assesses current condition of components

- F-19.02 Performs repairs, revisions and reinforcing of components

- F-19.03 Replaces components

- F-19.04 Performs preventative maintenance