Examination Weightings

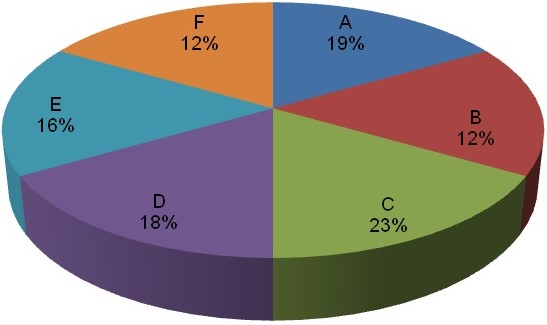

Pie Chart of Red Seal Examination Weightings

Text version

- Major Work Activity A - Performs Common Occupational Skills 19%

- Major Work Activity B - Performs Rigging, Hoisting/ Lifting and Moving 12%

- Major Work Activity C - Services Mechanical Power Transmission Components and Systems 23%

- Major Work Activity D - Services Material Handling/ Process Systems 18%

- Major Work Activity E - Services Fluid Power Systems 16%

- Major Work Activity F - Performs Preventative and Predictive Maintenance, Commissioning and Decommissioning 12%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada. The Task Matrix on the next pages indicates the breakdown of tasks and sub-tasks within each Major Work Activity and the breakdown of questions assigned to the Tasks. Interprovincial examinations typically have between 100 and 150 questions.

Industrial Mechanic (Millwright) - Task Matrix and Weightings

Major Work Activity A – Performs common occupational skills 19%

- Task A-1 Performs safety-related functions 17%

- A-1.01 Uses personal protective equipment (PPE) and safety equipment

- A-1.02 Maintains safe worksite

- A-1.03 Protects the environment

- A-1.04 Performs lock-out/tag-out and zero-energy state procedures

- Task A-2 Uses tools and equipment 21%

- A-2.01 Uses hand and portable power tools

- A-2.02 Uses shop machines

- A-2.03 Uses access equipment

- Task A-3 Performs routine trade tasks 26%

- A-3.01 Plans work

- A-3.02 Fabricates work piece

- A-3.03 Lubricates systems and components

- A-3.04 Performs leveling of components and systems

- A-3.05 Uses fastening and retaining devices

- A-3.06 Performs material identification

- A-3.07 Performs heat treatment of metal

- A-3.08 Uses mechanical drawings and schematics

- Task A-4 Uses communication and mentoring techniques 10%

- A-4.01 Uses communication techniques

- A-4.02 Uses mentoring techniques

- Task A-5 Performs measuring and layout 16%

- A-5.01 Prepares work area, tools and materials

- A-5.02 Measures material and components

- A-5.03 Lays out components

- A-5.04 Maintains precision measuring and layout tools

- Task A-6 Performs cutting and welding operations 10%

- A-6.01 Cuts material with oxy-fuel and plasma arc equipment

- A-6.02 Joins material using oxy-fuel welding equipment

- A-6.03 Welds material using shielded metal arc welding (SMAW) equipment

- A-6.04 Welds material with gas metal arc welding (GMAW) equipment

- A-6.05 Welds material with gas tungsten arc welding (GTAW) equipment (NOT COMMON CORE)

- A-6.06 Maintains welding equipment

Major Work Activity B – Performs rigging, hoisting/lifting and moving 12%

- Task B-7 Plans rigging, hoisting/lifting and moving 48%

- B-7.01 Determines load

- B-7.02 Selects rigging equipment

- B-7.03 Selects hoisting/lifting and moving equipment

- B-7.04 Secures area

- Task B-8 Rigs, hoists/lifts and moves load 52%

- B-8.01 Sets up rigging, hoisting/lifting and moving equipment

- B-8.02 Performs hoist/lift and move

- B-8.03 Maintains rigging, hoisting/lifting and moving equipment

Major Work Activity C – Services mechanical power transmission components and systems 23%

- Task C-9 Services prime movers 16%

- C-9.01 Installs prime movers

- C-9.02 Diagnoses prime movers

- C-9.03 Maintains prime movers

- C-9.04 Repairs prime movers

- Task C-10 Services shafts, bearings and seals 20%

- C-10.01 Installs shafts, bearings and seals

- C-10.02 Diagnoses shafts, bearings and seals

- C-10.03 Maintains shafts, bearings and seals

- C-10.04 Repairs shafts, bearings and seals

- Task C-11 Services couplings, clutches and brakes 16%

- C-11.01 Installs couplings, clutches and brakes

- C-11.02 Diagnoses couplings, clutches and brakes

- C-11.03 Maintains couplings, clutches and brakes

- C-11.04 Repairs couplings, clutches and brakes

- Task C-12 Services chain and belt drive systems 15%

- C-12.01 Installs chain and belt drive systems

- C-12.02 Diagnoses chain and belt drive systems

- C-12.03 Maintains chain and belt drive systems

- C-12.04 Repairs chain and belt drive systems

- Task C-13 Services gear systems 16%

- C-13.01 Installs gear systems

- C-13.02 Diagnoses gear systems

- C-13.03 Maintains gear systems

- C-13.04 Repairs gear systems

- Task C-14 Performs shaft alignment procedures 17%

- C-14.01 Performs rough alignment

- C-14.02 Performs dial alignment

- C-14.03 Performs laser alignment

Major Work Activity D – Services material handling/process systems 18%

- Task D-15 Services robotics and automated equipment 7%

- D-15.01 Installs robotics and automated equipment

- D-15.02 Diagnoses robotics and automated equipment

- D-15.03 Maintains robotics and automated equipment

- D-15.04 Repairs robotics and automated equipment

- Task D-16 Services fans and blowers 17%

- D-16.01 Installs fans and blowers

- D-16.02 Diagnoses fans and blowers

- D-16.03 Maintains fans and blowers

- D-16.04 Repairs fans and blowers

- Task D-17 Services pumps 21%

- D-17.01 Installs pumps

- D-17.02 Diagnoses pumps

- D-17.03 Maintains pumps

- D-17.04 Repairs pumps

- Task D-18 Services compressors 20%

- D-18.01 Installs compressors

- D-18.02 Diagnoses compressors

- D-18.03 Maintains compressors

- D-18.04 Repairs compressors

- Task D-19 Services process piping, tanks and containers 15%

- D-19.01 Installs process tanks and containers

- D-19.02 Installs process piping

- D-19.03 Diagnoses process tanks and containers

- D-19.04 Diagnoses process piping

- D-19.05 Maintains process tanks and containers

- D-19.06 Maintains process piping

- D-19.07 Repairs process tanks and containers

- D-19.08 Repairs process piping

- Task D-20 Services conveying systems 20%

- D-20.01 Installs conveying systems

- D-20.02 Diagnoses conveying systems

- D-20.03 Maintains conveying systems

- D-20.04 Repairs conveying systems

Major Work Activity E – Services fluid power systems 16%

- Task E-21 Services hydraulic systems 57%

- E-21.01 Installs hydraulic systems

- E-21.02 Diagnoses hydraulic systems

- E-21.03 Maintains hydraulic systems

- E-21.04 Repairs hydraulic systems

- Task E-22 Services pneumatic and vacuum systems 43%

- E-22.01 Installs pneumatic and vacuum systems

- E-22.02 Diagnoses pneumatic and vacuum systems

- E-22.03 Maintains pneumatic and vacuum systems

- E-22.04 Repairs pneumatic and vacuum systems

Major Work Activity F – Performs preventative and predictive maintenance, commissioning and decommissioning 12%

- Task F-23 Performs preventative and predictive maintenance 66%

- F-23.01 Performs preventative maintenance activities

- F-23.02 Performs vibration analysis procedures

- F-23.03 Performs balancing procedures

- F-23.04 Performs non-destructive testing (NDT) procedures

- F-23.05 Performs fluid analysis procedures

- F-23.06 Performs predictive maintenance activities

- Task F-24 Commissions and decommissions equipment 34%

- F-24.01 Commissions systems and components

- F-24.02 Decommissions systems and components