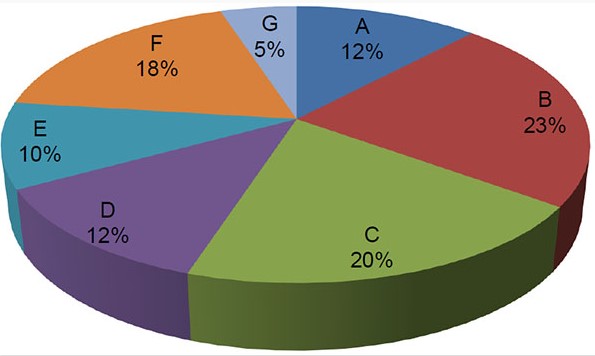

Examination Weightings

Pie Chart of Red Seal Examination Weightings

Text version

- Major Work Activity A - Performs common occupational skills 12%

- Major Work Activity B - Repairs frame and structural components 23%

- Major Work Activity C - Repairs non-structural outer body panels and related components 20%

- Major Work Activity D - Repairs mechanical, electrical and alternative-fuel system components 12%

- Major Work Activity E - Repairs interior components and services restraint systems 10%

- Major Work Activity F - Performs refinishing procedures 18%

- Major Work Activity G - Performs detailing and cleaning 5%

This pie chart represents a breakdown of the interprovincial Red Seal examination. Percentages are based on the collective input from workers from the trade from across Canada.

The following is the list of all of the Major Work Activities, Tasks and Sub-tasks. The percentages represent how the questions are assigned to each Major Work Activity and Task. Interprovincial examinations for this trade have 120 questions.

Task Matrix and Weightings

Major Work Activity A – Performs common occupational skills 12%

- Task A-1 Performs safety-related functions 11%

- A-1.01 Maintains safe work environment

- A-1.02 Uses personal protective equipment (PPE) and safety equipment

- Task A-2 Uses and maintains tools and equipment 17%

- A-2.01 Maintains hand and power tools

- A-2.02 Maintains frame and unibody repair and measuring equipment

- A-2.03 Uses lifting equipment

- A-2.04 Uses diagnostic equipment

- A-2.05 Maintains refinishing tools and equipment

- Task A-3 Uses and maintains welding equipment 17%

- A-3.01 Uses welding equipment

- A-3.02 Maintains welding equipment

- Task A-4 Organizes work and uses documentation 12%

- A-4.01 Prepares estimates and supplements

- A-4.02 Prepares repair plan

- A-4.03 Organizes parts, materials and work area

- A-4.04 Uses documentation

- Task A-5 Uses communication and mentoring techniques 8%

- A-5.01 Uses communication techniques

- A-5.02 Prepares repair plan

- Task A-6 Removes and installs trim and hardware 13%

- A-6.01 Removes trim and hardware

- A-6.02 Installs trim and hardware

- Task A-7 Performs final inspections 10%

- A-7.01 Performs final operational check

- A-7.02 Performs final quality control inspection

- Task A-8 Applies corrosion protection and sound deadening materials 12%

- A-8.01 Applies corrosion inhibitors and undercoats

- A-8.02 Applies seam sealers and sound deadeners

Major Work Activity B – Repairs frame and structural components 23%

- Task B-9 Prepares for repair and replacement of structural components 38%

- B-9.01 Identifies extent of damage

- B-9.02 Removes components for access

- B-9.03 Performs vehicle setup

- Task B-10 Repairs, removes and installs structural components 44%

- B-10.01 Repairs structural components

- B-10.02 Removes structural components

- B-10.03 Installs structural components

- Task B-11 Removes, installs and repairs structural and laminated glass 18%

- B-11.01 Removes structural glass

- B-11.02 Installs structural glass

- B-11.03 Repairs laminated glass

Major Work Activity C – Repairs non-structural outer body panels and related components 20%

- Task C-12 Removes, repairs and installs metal panels and components 46%

- C-12.01 Prepares metal panels and components for repair

- C-12.02 Removes metal panels and components

- C-12.03 Repairs metal panels and components

- C-12.04 Installs metal panels and components

- Task C-13 Removes, repairs and installs plastic and composite panels and components 37%

- C-13.01 Prepares plastic and composite panels and components for repair

- C-13.02 Removes plastic and composite panels and components

- C-13.03 Repairs plastic and composite panels and components

- C-13.04 Installs plastic and composite panels and components

- Task C-14 Removes and installs non-structural glass 17%

- C-14.01 Removes non-structural glass

- C-14.02 Installs non-structural glass

Major Work Activity D – Repairs mechanical, electrical and alternative-fuel system components 12%

- Task D-15 Deactivates and reactivates alternative-fuel systems 20%

- D-15.01 Deactivates alternative-fuel systems

- D-15.02 Reactivates alternative-fuel systems

- Task D-16 Removes and installs mechanical components 48%

- D-16.01 Removes mechanical components

- D-16.02 Installs mechanical components

- Task D-17 Removes, repairs and installs electrical and electronic components 32%

- D-17.01 Removes electrical components

- D-17.02 Repairs damaged wires and protective coverings

- D-17.03 Installs electrical components

- D-17.04 Services advanced electronic components

Major Work Activity E – Repairs interior components and services restraint systems 10%

- Task E-18 Repairs and replaces interior components 39%

- E-18.01 Repairs interior components

- E-18.02 Replaces interior components

- Task E-19 Services supplemental restraint systems (SRS) 61%

- E-19.01 Services seat belt restraint systems

- E-19.02 Services air bags and related components

Major Work Activity F – Performs refinishing procedures 18%

- Task F-20 Prepares surface 25%

- F-20.01 Performs initial preparation

- F-20.02 Masks surface

- F-20.03 Strips surface

- F-20.04 Sands surface

- Task F-21 Uses repair materials 13%

- F-21.01 Mixes repair materials

- F-21.02 Applies repair materials

- Task F-22 Prepares refinishing equipment 13%

- F-22.01 Prepares spray booth

- F-22.02 Performs spray gun setup

- Task F-23 Prepares refinishing materials 17%

- F-23.01 Mixes refinishing materials

- F-23.02 Performs colour adjustments

- Task F-24 Applies refinishing materials 23%

- F-24.01 Applies sealers

- F-24.02 Applies base coat

- F-24.03 Applies single-stage paint

- F-24.04 Applies clear coat

- Task F-25 Performs post-refinishing functions 9%

- F-25.01 Removes masking materials

- F-25.02 Corrects surface imperfections

Major Work Activity G – Performs detailing and cleaning 5%

- Task G-26 Details exterior 61%

- G-26.01 Removes minor imperfections

- G-26.02 Polishes vehicle

- G-26.03 Touches up stone chips

- Task G-27 Cleans vehicle 39%

- G-27.01 Cleans exterior

- G-27.02 Cleans interior